Speed of Air

DFC Diesel has partnered with Speed of AirTM to develop a game changer crate engine product for medium duty diesel applications. We have been independently testing over a dozen trucks across DODGE, FORD and CHEVY engine platforms and the results so far have been amazing! Increased fuel mileage, improved drivability/power, reduced operating costs, smoother running and reduced emissions!

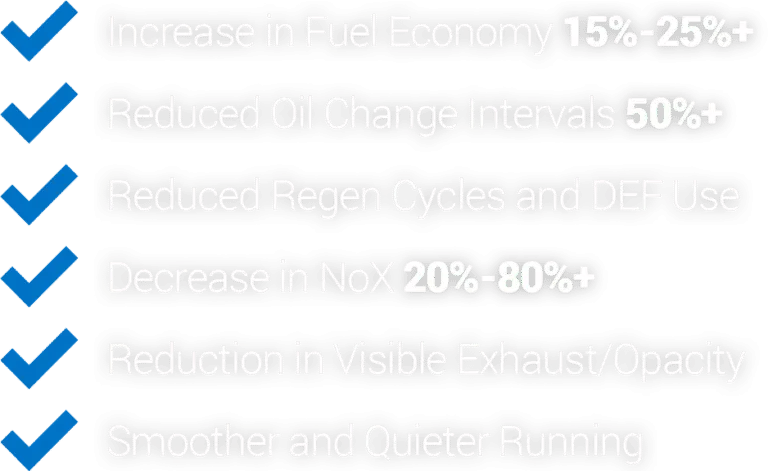

What We’ve Observed

To the best of our ability we tested these trucks on a state of the art Mainline© Eddy Current Hub Dyno and utilized a Kane 5 gas analyzer on the dyno, and on road, to gather data. After baseline testing the engines are equipped with Speed of AirTM treated Hyperformance PistonsTM and Total Seal® Gapless ring sets. Our testing continues to indicate consistent, positive improvement. We continue to add trucks for testing.

Break in period

Speed of Air Hyperformance pistons come coated with an abradable Line to Line coating that will wear to the correct size within the first few hundred kms/miles of run time. The engine can be put under full load once has achieved normal operating temperatures under light driving. The first oil change should be performed within 1,000kms (600 miles) and again after 4,000kms (2,500 miles) before resuming to regular oil change intervals. No towing should occur within the first 1,000kms (600 miles). The coating allows millions of microscopic oil cavities to hold oil between the piston skirt and cylinder wall and will be fully clearanced after the first time under consistent heavy loads such as towing.

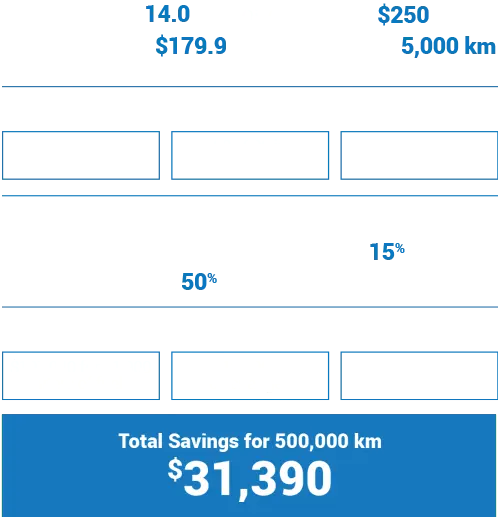

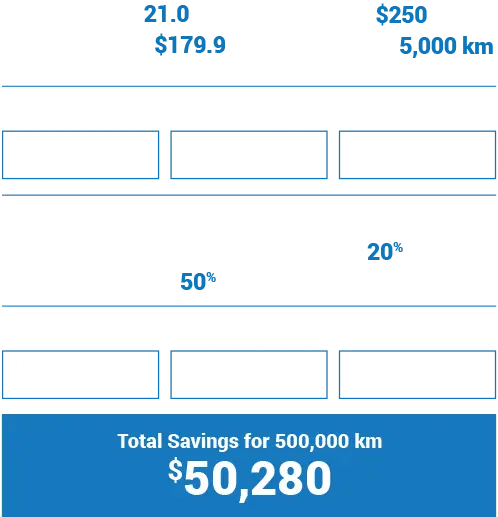

Mileage

On all of our test vehicles we noticed improved mileage became much more evident after the engine was fully broken in and/or after the first time the truck towed a trailer. As these engines are built with longevity as a primary focus the Line to Line coating and Total Seal rings may need up to 10,000kms (6,000 miles) to be fully broken in and best results observed. Utilizing a break in oil during the first 1,000kms (600 miles) may help produce faster results.

Emissions

All 20+ trucks in our test fleet consistently showed a decrease in NOx at all engine loads and speeds with an increase in oxygen out the exhaust pipe. Speed of Air Hyperformance pistons allow the engine to burn more of the available fuel in the cylinder resulting in it being cleaner burning which in turn improves fuel mileage as well. All of our test vehicles had observable decrease in smells, odors and visual hazing at idle after swapping engines out with the only change being SOA piston technology.

Drivability

Your new SOA equipped engine is going to have a noticeable improvement and feel to the driver with how responsive the turbo is and the perceived feel of low end torque. As the engines burn cleaner you will notice the turbo spools quicker resulting in more usable low end power which allows your truck to get up to speed with less throttle input and maintain speed on hills easier when towing. While the peak HP and Torque numbers do not see any significant gains we have observed the trucks often having several hundred ft/lbs of torque lower in the rpm band which is what makes such an improvement in how the trucks drive. Most owners reported the most observable different after the first 1,000km (600 miles) of driving.

EGTS

As our test vehicles had a wide range of modifications from stock to as much as 668 rwhp all of them experienced a reduction in peak EGT’s typically 100-200 degrees Fahrenheit.

Oil changes

After the engine is fully broken in you will be able to extend your oil change intervals at least 50% from what is normally required so if your application requires oil changes every 5,000km (3,000mi) you can now extend to 7500km (4,500mi). This is possible because with SOA technology you are having a significant reduction in unburnt fuel and the Total Seal rings reduce fuel dilution of the crankcase.

DPF/DEF

Once your new DFC SOA equipped engine is installed you will begin seeing a decrease in the frequency of regen cycles and consumption of DEF exhaust fluid. Results will vary depending on your trucks mileage and how plugged your factory exhaust is but due to how clean the engine will be running some test trucks have virtually stopped doling regen cycles.

The SoA patented technology primarily consists of precise, CNC-machined indentations on the piston top, called turbulators, but most often described simply as “dimples.” This precisely designed and manufactured technology is executed to exacting tolerances under ISO 9001 quality standards. These turbulators create a thinner, well-attached boundary layer between the air-fuel mixture, its flame front and the combustion chamber walls. This thin, turbulent layer allows the combustion flame front to burn much closer to the cool metal walls of the combustion chamber, thereby increasing overall combustion efficiency. The result is significant reductions in fuel consumption, reduced emissions, increased torque and horsepower, improved drivability and pulling power. Lower soot emissions translates to better engine longevity and fewer service intervals.

SOA’s Hyperformance pistons also includes the application of aerospace-proven thermal barrier and anti-friction coatings on the piston crowns and skirts, respectively. The thermal barrier coating retains heat in the combustion process, thus providing additional efficiency and power. The anti-friction coating minimizes abrasion and resistance for even more efficiency. The combined technologies of a Speed of Air Hyperformance piston provide documented and significant benefits with a distinct value proposition.

To manufacture these custom piston kits, SoA has licensed United Engine and Machine Co. (UEM), a leading manufacturer of pistons with over 100 years of experience and a well-earned reputation for quality. As a family-owned and operated company, UEM has in-house design, development and manufacturing capabilities that allow this firm to meet nearly every type of engine’s piston needs.